If you’re planning to install hand dryers in public facilities, one of the first questions that often comes up is whether they need special electrical wiring. It’s a common consideration, especially if you’re upgrading an existing space or working within a tight refurbishment budget. The good news is that, in most cases, modern hand dryers are straightforward to install and don’t require anything out of the ordinary.

That said, there are a few important electrical considerations to be aware of. Understanding these early on can help avoid delays, ensure compliance and make the installation process much smoother.

The Short Answer

Most hand dryers do not need special electrical wiring. The majority of modern commercial hand dryers are designed to run on a standard mains electricity supply commonly found in UK buildings. As long as a suitable power source is already available nearby, installation is usually simple.

However, factors such as the number of dryers being installed, their power rating and the existing electrical capacity of the building can influence what’s required. This is where a little planning can make a big difference.

Typical Electrical Requirements for Hand Dryers

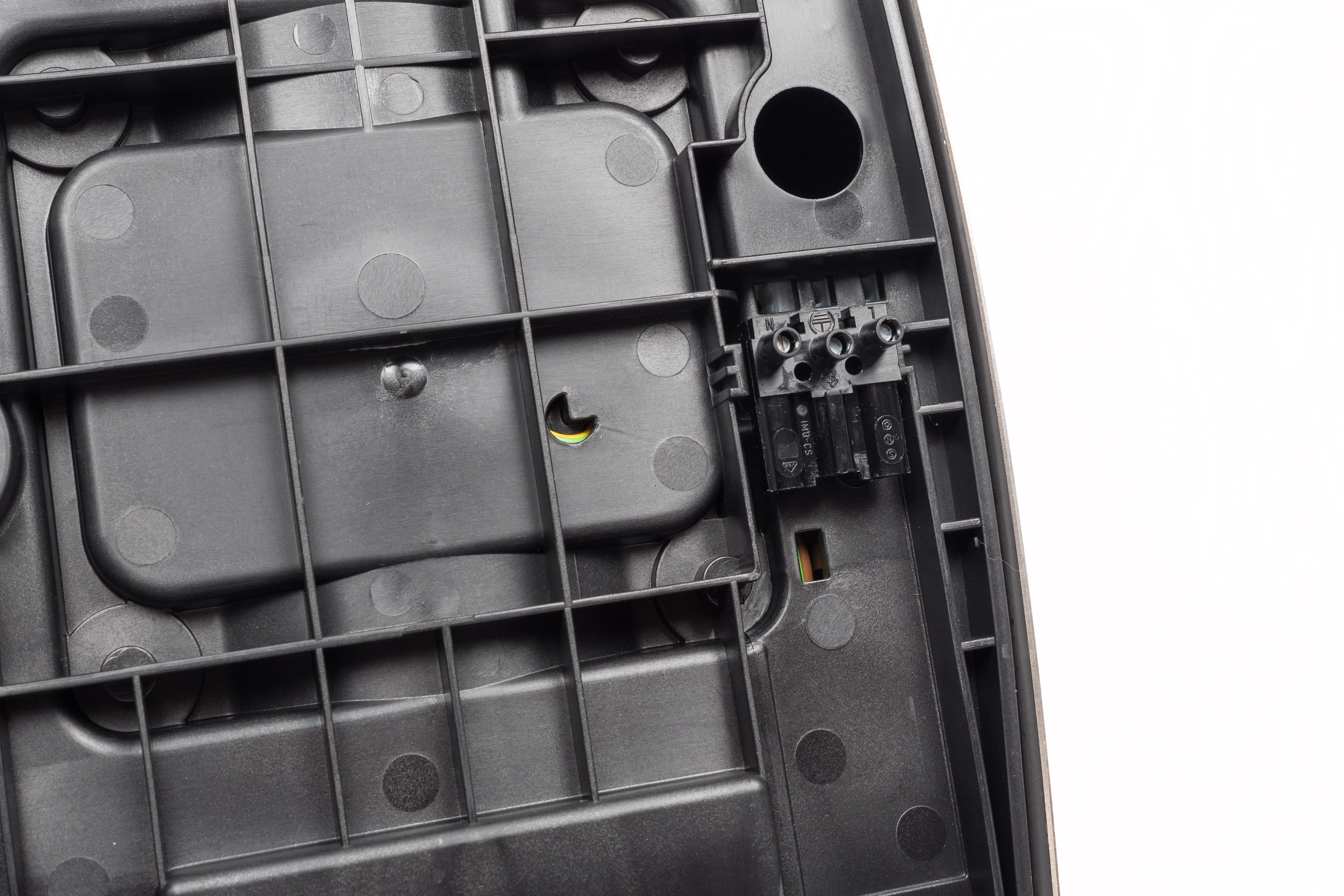

Because hand dryers are permanently connected, installation should always be carried out by a qualified electrician to ensure the correct cabling, isolation and protection are in place. While this doesn't usually mean complex or specialist wiring, it does mean the electrical connection must meet current safety regulations and manufacturer requirements.

Do High-Speed Hand Dryers Need Different Wiring?

High-speed hand dryers often sound more powerful, which can make people assume they need specialist wiring or a higher electrical supply. In reality, many modern high-speed models are designed to be highly efficient, using clever motor technology to deliver fast drying times without dramatically increasing energy use. This means they are often no more demanding to install than standard hand dryers.

In practical terms, most high-speed hand dryers can be connected using the same type of electrical supply as other commercial dryers. The key is to check the specific power rating of the model and ensure the existing circuit has enough capacity. A quick assessment by a qualified electrician is usually all that’s needed to confirm everything is suitable and safe before installation.

Dedicated Circuits and Electrical Load Considerations

In some commercial settings, a dedicated electrical circuit is recommended for hand dryers, particularly when several units are installed close together. This is most common in larger public facilities, leisure facilities or transport hubs where dryers may run almost continuously during peak times. A dedicated circuit helps ensure consistent performance and reduces the risk of nuisance tripping when demand is high.

It is also worth considering what else is connected to the same circuit. Lighting, heaters or other equipment can quickly add to the electrical load. Spreading demand across circuits helps protect the system and can extend the lifespan of both the hand dryers and the building’s electrical infrastructure.

Electrical Safety, Compliance and UK Regulations

Any hand dryer installed in the UK needs to be fitted safely and correctly. In commercial and public buildings, this means following BS 7671 (the IET Wiring Regulations), which are widely used as the standard for safe electrical installations. This is especially important in environments where water exposure and frequent use are common, as these factors can increase the risk of electrical issues if equipment is not installed properly.

In commercial settings, getting this right really matters because responsibility extends to employees, customers and the wider public. Electrical work must also meet the requirements of the Electricity at Work Regulations 1989, and using a qualified electrician helps ensure everything is compliant, safe and built to perform reliably over the long term.

Installing Hand Dryers in Existing Buildings vs New Builds

In new build projects, installing hand dryers is usually very straightforward. Because the layout and electrics are planned from the start, power supplies, isolation switches and cable routes can be designed around the dryers. This makes fitting them quicker and often more cost-effective, with fewer surprises once installation begins.

In existing buildings, the process is still typically simple, but it usually starts with checking what’s already in place. Older buildings may have limited electrical capacity or circuits that need a small upgrade to support new equipment. This doesn’t usually mean major disruption, but it does underline the value of assessing suitability early on. A quick check upfront can help avoid delays and make the installation run much more smoothly.

How Power Consumption Impacts Wiring Decisions

Modern hand dryers are much more energy efficient than older models, and that has a real impact on how they’re wired. Lower wattage dryers place less demand on electrical systems, which often makes them easier to install on existing circuits without the need for upgrades. This can be especially helpful when retrofitting dryers into offices, schools or public buildings where the electrics weren’t designed with high-powered equipment in mind.

Knowing a dryer’s power rating allows electricians to plan the installation properly, from checking circuit capacity to choosing the right cabling and protection. Selecting an efficient model can make the whole process simpler, keep energy costs down and support sustainability goals, all without sacrificing performance.

Why Professional Installation Makes a Difference

Hand dryers aren’t especially complicated pieces of equipment, but how they’re installed can make a real difference over time. A professional installer knows where a dryer should be positioned correctly, how to route cables neatly, and where to place isolation switches so they’re accessible. These might seem like small details, but they have a big impact on how practical and reliable the dryer is in everyday use.

Having the installation done properly also helps reduce the chances of problems later on, such as faults, downtime or avoidable callouts. In busy public facilities with high usage, where dryers are used constantly, getting it right from the start helps keep things running smoothly and avoids unnecessary disruption or extra maintenance costs.

In summary, hand dryers rarely need special electrical wiring, but thoughtful planning is important to ensure safe, reliable performance. Factors such as building age, electrical capacity and usage levels all play a role in determining whether upgrades or dedicated circuits are beneficial. With modern energy efficient dryers and proper installation, most public and commercial facilities can be upgraded smoothly without major electrical work.

If you’re not sure whether you might need to carry out electrical upgrades or would like some advice before installing hand dryers, our team is happy to help. Get in touch and we’ll guide you through the requirements and help ensure everything runs smoothly from start to finish.