Why Intelligent Hand Dryers Is the Best Place to Buy Electric Hand Dryers

At Intelligent we pride ourselves on being the market leaders in our industry. For the past 13 years we’ve worked hard to set ourselves from our competitors every day. In...

Call for expert advice: 0114 3540047 or 0203 3270448

At Intelligent we pride ourselves on being the market leaders in our industry. For the past 13 years we’ve worked hard to set ourselves from our competitors every day. In...

This article breaks down the key elements of a compliant Doc M shower layout, including the most important Doc M shower dimensions and fixture requirements.

As part of our series on Doc M basics, this post looks at Doc M toilet layouts and dimensions.

In this post we’re going to look at the basics of Doc M layouts: what the dimensions are, what fixtures are needed and some other considerations.

What exactly is it that users want from a washroom? In this post we’re going to draw on our 10 years of experience of supplying commercial washrooms, and talk about...

Installing a baby changing unit, while not a legal requirement, is a considerate and intelligent thing to do. And, given the costs and ranges now available, they don’t have to...

Ensuring the right number of toilets in a restaurant isn’t just a matter of convenience—it’s a legal requirement. Whether you’re opening a new venue or refurbishing an existing one, understanding...

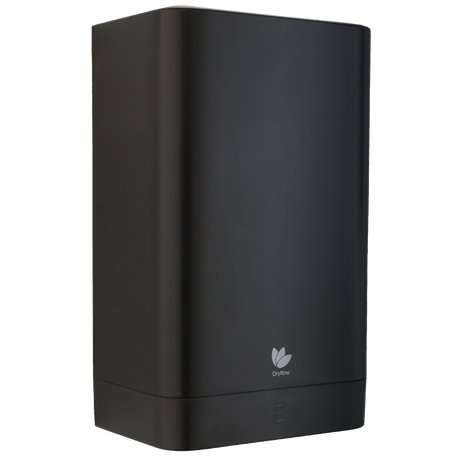

Dryflow Connect The Dryflow Connect is one of the most recent additions to the Dryflow range. Dryflow claim you can say goodbye to lengthy installations! The Connect can be installed in...

Imagine stepping into a washroom where the fixtures are tarnished with rust, surfaces bear the marks of persistent grime, and the whole thing smells like the 90s. Such environments not...

In this post we’re going to explore those ranges and discuss what kind of washroom they could suit the most. Of course, our suggestions are just that, suggestions, and we...

Refurbishing your business's washroom is more than just a cosmetic upgrade, it's an opportunity to enhance functionality, ensure compliance with regulations, and improve the overall user experience. In this post...

Office washrooms are more than just functional spaces, they can significantly influence employees' perceptions of your company which in turn can impact overall satisfaction and productivity. Recognising when it's time...

The school had conventional hand dryers in place that were about 15 years old. They had a slow dry time of around 30 seconds and a rated power of 2300 kW, which isn’t very...

The updated 'Best Commercial Hand Dryers in 2025 list' has been compiled based on a scoring criteria for speed, energy-efficiency, quiet operation, vandal resistance, life expectancy and overall value.

First published 11/11/22 Last updated 04/02/25 Soap dispensers, especially those with the ability to use alcohol gel, are a very popular addition in most facilities. They are not only used...

The Bobrick B-3725 is part of the TrimLine series. It is a recessed hand dryer, which has anti-vandalism protection, a brushed satin finish and a long guarantee of 5 years....